- Home

- Product catalog

- Catalog

- Bearings, conveyor units and elements

- Cable and wire products

- Compressor equipment and components

- Hydraulic equipment

- Industrial electronics

- Industrial pumps

- Industrial tools and materials

- Machines and components

- Pipeline accessories

- Pneumatic equipment

- RTI (Rubber products)

- Technological equipment and inventory

- Test equipment

- Ventilation equipment

- welding equipment

- Products in stock

- About us

- Delivery and payment

- Articles

- Contacts

Air Handling Unit: The Key to Clean Air in the Pneumatic System

- Publication Date:

- 15 July 2021 г.

A hydraulic pump is one of the main components of any hydraulic system. It is designed to pump pressurized liquids through hydraulic systems. Hydraulic pumps boast high performance (except for manual models), durability, and are widely used in machinery.

For any pneumatic system to be effective, the purity of compressed air jets supplied by the compressor is essential. The ambient air the compressor sucks can contain dust particles, moisture, and other impu[Привлеките внимание читателя с помощью яркой цитаты из документа или используйте это место, чтобы выделить ключевой момент. Чтобы поместить это текстовое поле в любой части страницы, просто перетащите его.

rities that adversely affect pneumatic equipment. It is not enough to

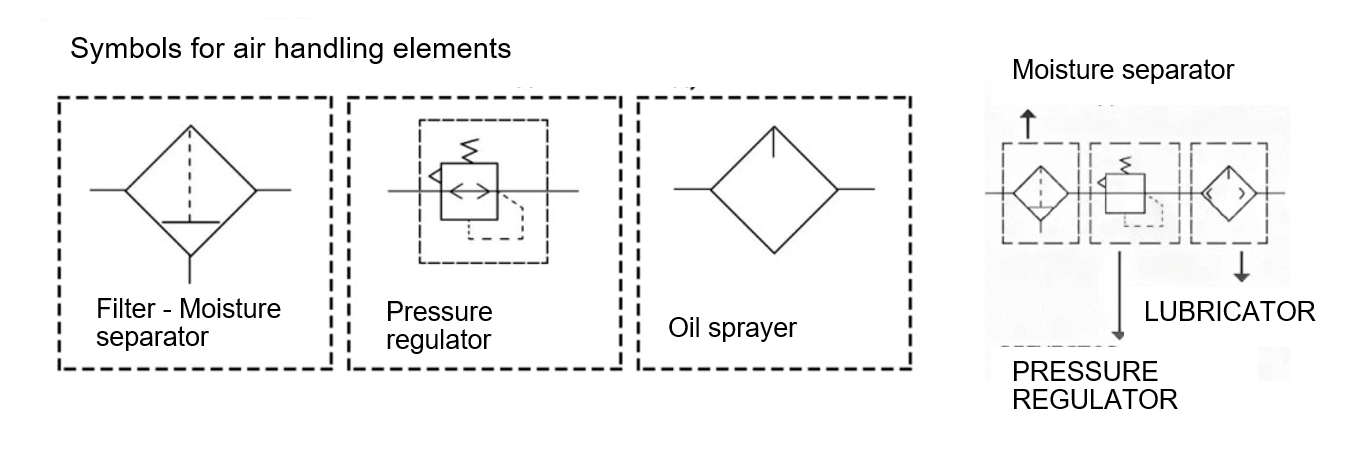

Air handling unit. Main structural elements

An AHU has a modular design that includes specific components depending on the intended use of the unit. All elements are integrated in a common housing with channels and mounting points. The components are arranged in such a way that the air is first cleared of mechanical particles, moisture, purified or enriched with oil (depending on system requirements), and then passed through the valves and reducer.

Reducer that regulates air jet pressure

This component allows the compressed air pressure to be maintained within specified limits. It is installed at the AHU outlet.

Filter

The purpose of a AHU filter is to remove mechanical particles from the jet. This element can be installed separately or as part of moisture or

Integrated models allow reducing the dimensions of the entire unit.

Particulate filters are divided according to their purification level:

- coarse (Q) — particles of 5–40 µm;

- fine (P) — up to 1 µm;

- micro (D) — up to 0.01 µm.

Moisture separators

Adsorption moisture separators, in which vapor and condensate are absorbed by a granular adsorbent, are the most widely used. The absorber saturated with moisture, it is regenerated by pushing air in the opposite direction, thus draining the collected moisture into the environment.

Oil separators

Oil separators remove oil droplets that enter the air jet from the compressor’s lubrication system, which is connected to the engine’s lubrication system. These are used in complex pneumatic systems with numerous valves and taps. Typically, in pneumatic systems of vehicles and industrial equipment.

Lubricator

An AHU lubricator is intended for saturating air jets with oil droplets to lubricate rubbing mechanisms of pneumatic tools and pneumatic equipment. Lubricators are used in air supply systems for pneumatic tools at service stations and assembly lines.

Additional equipment

AHUs used in industrial pneumatic systems often have additional valves installed. These allow for a smooth

Selecting an air handling unit for your specific application

When selecting the AHU configuration, consider all features of the pneumatic system to be serviced. Applications (without limitation):

- vehicles and tractors — reducer, particulate filter,

oil-and-moisture separator; - pneumatic systems of pneumatic tools and pneumatic equipment — filter, reducer, moisture separator, lubricator;

- industrial pneumatic systems — selecting components depends on the characteristics the pressurized air jet requires.

Maintenance is essential for AHUs to operate smoothly. The maintenance consists of cleaning or replacing the filter, adding oil to the lubricator, and regenerating the adsorbent.

© 2024 Stemag Group